The tragic death of Rebecca Finch following a fire in Warwick last month is being blamed on an overloaded socket outlet. Although I’m not privy to the investigation into the cause of the fire, it is worth penning a general article on how to avoid overloading electrical outlets because something as mundane as using an electrical socket shouldn't be costing anybody their life.

There are safety measures which should mean that any socket is capable of safely delivering electrical current both during normal operation and under fault conditions without it exceeding its limitations. From fuses or circuit breakers, to the installation meeting the requirements of the wiring regulations, if it's been done right then an overload shouldn’t happen. So, what could have gone so terribly wrong here?

Shame the headline hack couldn't resist penning a pun considering the dreadful circumstances.

I noticed this story in the Leamington Observer last week, issue dated 2nd March 2017, and I have worked for another tenant in that very block of flats in Humphris Street a few years ago. According to an updated article on the newspaper’s website, it seems smoke inhalation was the cause of death for the unfortunate Ms Finch. I don’t know if a working smoke alarm was fitted in this case, but it would be remiss of me to write this without mentioning that every home should have operational smoke alarms that are in date and tested regularly. Smoke alarms have an expiry date of about ten years, and even many mains powered models require a backup battery to be replaced every twelve months.

However effective your smoke alarm, prevention of an electrical fire is better than being woken up to the incessant chirping of an alarm, so here’s a quick run-down of how any given socket outlet could be stressed to the point of ignition.

Too many appliances

Most homes, especially older properties, lack the physical number of socket outlets we require for 21st century living, so we’re all used to adding in multiway adaptors and sometimes even daisy-chaining them. Doing this isn’t ideal, but so long as the host adaptor, i.e. the one plugged into the socket itself, is fused, then it shouldn’t be possible for the appliances downstream to overload the capacity of the socket. That said, a 13A fuse in a plugtop or adaptor won’t really blow at 13A and a couple of high load appliances may pull an average current close to the limit of the fuse for a prolonged time causing it to heat up but not to blow. If you’ve ever found a plugtop to be hot, or noticed discolouration or heat damage around the plugtop pins or socket holes, then this is likely to be what’s happening. You should evaluate the loads being pulled through that plug – small devices such as phone chargers won’t be drawing a significant current, but appliances with heaters or motors such as washing machines, dryers, fan heaters, toasters and kettles certainly will be. If any given room lacks enough outlets to serve the appliances located within, then get more outlets professionally fitted because a hot plug/heat damaged socket will eventually fail and perhaps in a firey way. If the wiring behind it becomes damaged, then repair will be more expensive than if you'd had the issue corrected before it was too late. In the meantime, ration the loads – i.e. don’t use the washing machine and the dryer together or the kettle and the toaster at the same time.

Non-compliant adaptors and chargers

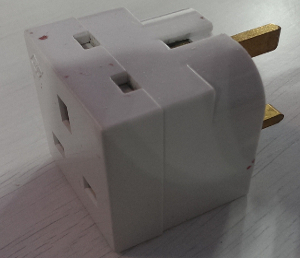

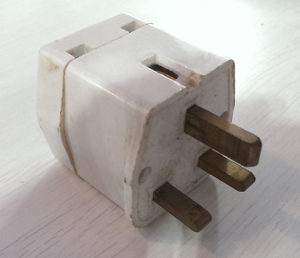

In the previous paragraph, I mentioned plugtops becoming heated from there being a prolonged heavy load pulled through the fuse:- one high enough to heat it but not enough to blow it. What then if no fuse is fitted at all? Some older adaptors lack a fuse altogether, while counterfeit ones which do not comply with BS1363, the British Standard for plugs and sockets, may lack many safety features or contain a pretend fuse which itself doesn’t comply with BS1362, the British Standard for plugtop fuses. Always buy multiway adaptors from a known source such as a high street or supermarket chain, never from iffy market stalls or internet sites, and certainly not from the likes of eBay. The world is awash with electrical rubbish which does not meet British or European standards despite fake kitemarks and CE stamps. We keep hearing about fires caused by knock-off chargers and battery packs, but the same applies to extension leads and distribution strips – buy a genuine brand from a known retailer.

|

|

|

| This multiway cube lacks a fuse and shouldn't be used. | This early-Eighties multiway cube also lacks a fuse and sleeving on the live/neutral pins. |

Incorrect fusing

BS1363 is a fantastic plug and socket standard, maybe the best in the world as I’ve blabbed on about before, but it does have one weakness – fuses are interchangeable regardless of their rating. This means a 13A fuse can be fitted into a plugtop where a 3A or 5A fuse should be fitted as a maximum. The size of fuse depends on the thickness of the cable coming from the plug. A cable with conductors of 0.5mm2 or 0.75mm2 may require a 3A or 5A fuse, while a 1.5mm2 or 2.5mm2 cable might have a 5A or 13A fuse. If you have a string of Christmas tree lights, then they would have a thin cable and require a 3A fuse, but say that fuse blew when a lamp failed and your kitchen drawer of odds n’ sods only has a pack of 13A fuses available? It would be easy to retrofit a 13A fuse and sure enough those lights would be working again with the failed lamp replaced, but next time a lamp fails as a short circuit, a far larger fault current will be permitted before the replacement fuse finally blows. In fact, the fault current may be large enough for the wires to heat up and burn long before the fuse does so. This was, I’m sure, the cause of many a festive fir flare-up before low voltage LED lights started adorning our Christmas trees of late, but it illustrates the point. I’ve also come across fuses being replaced with nails or copper wire which removes the local failsafe entirely and leaves the load cable to cope with a fault current potentially running into many tens of amps before a fuse or breaker back at the distribution board kicks in, but by then it’ll be too late.

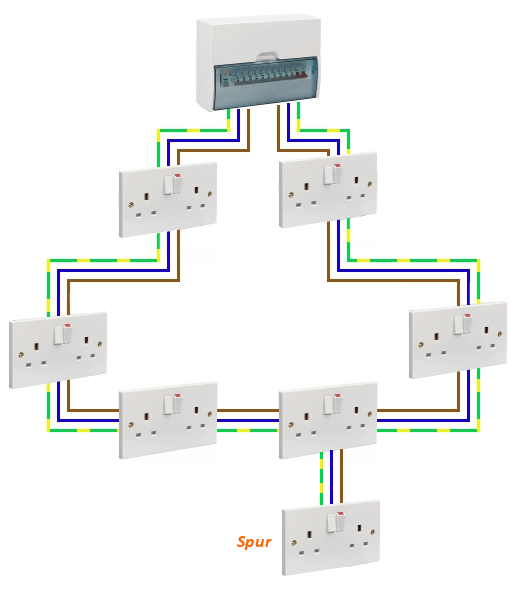

Ring breaks

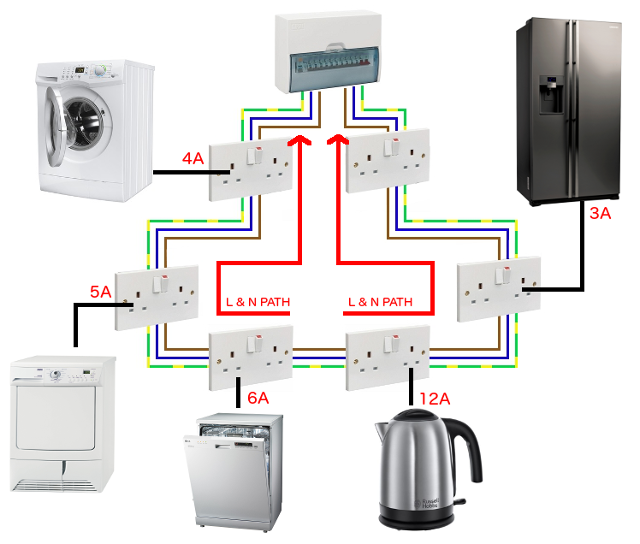

In most domestic properties in the UK, socket outlets are installed in a ring configuration – that is to say the wiring comes from the consumer unit, passes through each socket in the chain and eventually goes back to the consumer unit as depicted below.

In this simplified example, the wiring on the left side of the ring has a load of 15A from the washing machine, dishwasher and dryer, while the wiring on the right side of the ring carries the 15A load from the kettle and fridge. The total load current is within the 32A rating of the circuit breaker, and the wiring on both sides of the ring is capable of carrying their respective loads.

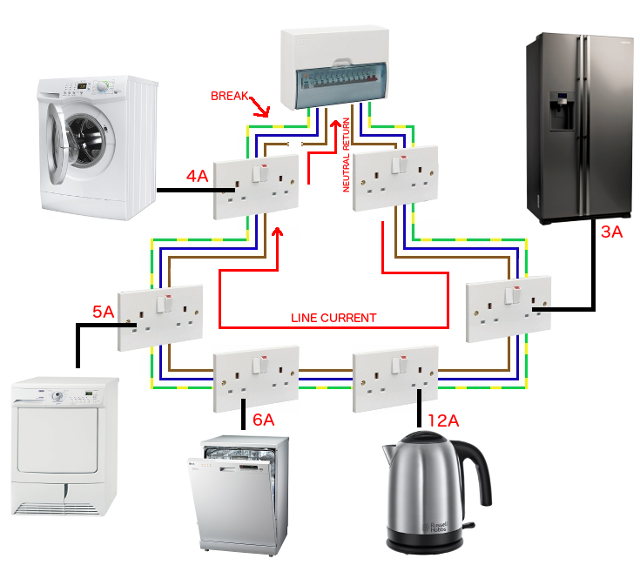

The ring configuration gives the load appliances on the socket circuit two parallel paths back to the consumer unit, spreading the load current. This allows us to use thinner wires while retaining a relatively high source of supply (30A to 32A). The ring thing is a throwback to the aftermath of WW2 when copper was in short supply and it has hung around ever since, although personally I’m not a fan. The problem with rings is that if there is a break then you lose the parallel path, and suddenly these thinner wires are at risk of coping with more current than they are designed for. Because the source is protected by a 30A fuse or 32A breaker, the wiring serving the ring can become overloaded under normal (non-fault) conditions and despite the wiring being overloaded, it being a normal load current and not a fault current means the protective device won't operate.

With a ring break in the line wiring as shown, the neutral return of the washing machine, dryer and dishwasher still passes down the wiring on the left, but now all appliances are taking their supply from the right side of the ring. The portion of the wiring between the consumer unit and fridge is now carrying a total load of 30A which won't trouble the 32A circuit breaker, but the wiring at this point may have a maximum rating as low as 18A depending on how it was installed and how well it can dissipate the heat caused by the overloading. If it cannot dissipate the heat, it will eventually reach the point of ignition.

With a ring break in the line wiring as shown, the neutral return of the washing machine, dryer and dishwasher still passes down the wiring on the left, but now all appliances are taking their supply from the right side of the ring. The portion of the wiring between the consumer unit and fridge is now carrying a total load of 30A which won't trouble the 32A circuit breaker, but the wiring at this point may have a maximum rating as low as 18A depending on how it was installed and how well it can dissipate the heat caused by the overloading. If it cannot dissipate the heat, it will eventually reach the point of ignition.

So how do you know if your socket ring is healthy? Sadly, the only way to find out is to fork out for an electrician to perform an electrical inspection and to provide a full Electrical Installation Condition Report (EICR). It’s wise to have this performed at least every ten years domestically, and if you’re renting then you should insist the landlord cough up for one at least every five years. Just make sure your chosen sparkie is qualified and accredited for such work as I’ve come across some before who are not (see the Cowboy Competition entries of my blog). A sticker on the consumer unit should indicate when the last inspection was undertaken and when the next one is due.

Spur sockets

Is your socket outlet a spur? There’s a question you’ll be unlikely to be able to answer unless you appointed an electrician to install a particular outlet and you know from their paperwork that it was installed as such. What is a spur? Well, I’ve already talked about the ring configuration, but a new socket installed later may not be fitted as part of the ring, and instead branch off from it on its own.

I mentioned previously that a ring circuit uses thinner cables, but this same thin cable can be used to provide a spur socket so long as only one accessory is being supplied (i.e. one single socket outlet or one twin socket outlet). This is fine for a low current application such as a child’s nursery where multiple high-current appliances are less likely to be operating simultaneously. In an adult’s bedroom, it may be a problem because there’s nothing stopping an unfused multiway adaptor being fitted to increase the physical number of socket outlets, and if there’s a girl’s night out on the cards with a hair dryer, curling tongs and other such loads with heating elements operating at the same time then we’re again in a position whereby the cable feeding the socket is handling more current than it was designed for. As before, it’s a normal load current, not a fault current, so the protective device back at the consumer unit will let it pass without blowing or tripping, but the wiring to that socket is going to heat up, and if exposure is prolonged then it could ignite. Spurs that may be subject to a heavy load should either be fused or be supplied by a fatter cable to ensure there is no risk of them becoming overloaded.

Coiled extension leads

Another subject I’ve talked about before are extension leads and the fact they can be bought in ridiculous lengths which would see them technically fail a PAT test through high earth loop impedance as soon as they leave the factory. You might think that buying a 45 metre extension reel should see you through any eventuality, but reel leads should be fully unwound before use and unwinding/winding quickly becomes a chore causing many people to just pull off the few metres they need and leave the rest coiled. This has two negative effects. Firstly physics students will remember that passing an electric current through a tightly wound coil makes an electromagnet, and electromagnetism induces a back EMF which opposes the current flow down a wire and increases impedance. A rise in impedance causes a rise in temperature which increases the resistance of the wiring which causes a rise in temperature and... well, you can see where this is going. Secondly, the wiring within the tightly wound coil cannot dissipate its heat, so it just gets hotter and hotter. If left long enough, a coiled extension lead will turn into a molten doughnut. When buying a coiled extension lead, go for one with a sensible lead length, say five metres if that’s all you’re really likely to be needing it for, and fully unwind it before use. These things are really designed for temporary use around the home or garden when mowing the lawn or doing a spot of DIY, they shouldn’t be used as a semi-permanent solution if you have a lack of sockets in any given room of your home.

Loose, worn or dirty connections

A plugtop or socket with poor connectivity through a bad connection or dust/dirt having gotten into it can suffer from a high resistance joint and as mentioned previously, resistance causes heat which causes resistance which causes heat.... So, how do you know if you have a problematic plug and socket combo? Tell-tale signs include difficulty inserting or removing plugtops from the socket, obvious signs of dirt or grease build up, having to wobble or adjust a plug to get it to work, crackling noises, visible sparking, having to repeatedly flick the socket switch on and off until it starts working, signs of physical damage such as scorching or cracking around the plug pins or socket faceplate, being hot to the touch and nasty ‘fishy’ electrical burning odours. If any of this sounds familiar, refrain from using the socket further until you’ve had it professionally checked out.

Old/poor/damaged wiring

An older installation may have wiring that should be replaced because the rubber insulation has perished or the aluminium conductors have become brittle or reacted with copper terminations. Newer wiring in PVC clad copper is more resilient, but even then it may be damaged by rodents, water, crushing, overbending, UV exposure, poor installation, inappropriate modification and other such factors. If your wiring isn’t in good condition, then proper use of an electrical outlet, let alone improper use, may well see an electrical fire break out. As before, a condition report from a qualified and accredited electrician will tell you if any alarm bells are ringing before your smoke alarms start doing so.

Non-compliant wiring

As you may expect, I have seen some dreadful breaches of the wiring regulations in my time, from misguided DIY efforts to builders, plumbers and fitters who have all chanced their arm and walked away leaving something that works but would be incredibly dangerous in the event of a fault. Whether it’s incorrectly rated protective devices, undersized cabling, inappropriate fittings, poor terminations or whatever, a socket outlet, like any other part of the electrical installation, should be installed to a design that complies with the wiring regulations so that it operates safely under normal conditions and under fault conditions. That is to say, whatever the end user is plugging into that socket, it should work, and if the appliance is faulty then there should be some kind of protection to prevent the wiring from bursting into flames. I’m not talking about the safety of the appliance itself here, it’s down to the manufacturer of the hair dryer or washing machine to ensure their appliance operates safely, but in the event of a fault, the design of the fixed wiring of the circuit itself should ensure that a fuse or breaker cuts the power before a cable can become overloaded. If you’re having electrical work performed by a trade such as a builder or bathroom fitter, ensure they appoint a qualified electrician for the wiring work and get the certificate of compliance off them afterwards.

We all know electricity can be dangerous stuff, but we should be able to use it in our daily lives without getting too paranoid that it's going to turn on us at any moment. Most of the above is common sense - appoint professionals to work on your electrical installation, buy branded appliances from familiar reputable retailers, don't plug in anything when there are signs of damage, discolouration, or other thermal effects either on the appliance or the socket outlet, unplug anything that's not operating properly and have your electrical installation inspected periodically.

If in doubt, leave the plug out. At least until you can seek professional advice.